Анализаторы руды и пульпы

Точный анализ для эффективных процессов добычи

Преимущества

Научный потенциал

работу курирует кандидат физико-математических наук, защитивший диссертацию

Обширные знания и опыт

опыт компании - более 15 лет интенсивной работы в области решения задач

Работа под ключ

весь цикл работ - от первого обращения до внедрения оборудования

Cобственные исследования

беремся за решение сложных задач по анализу элементного состава на предприятиях

О нас

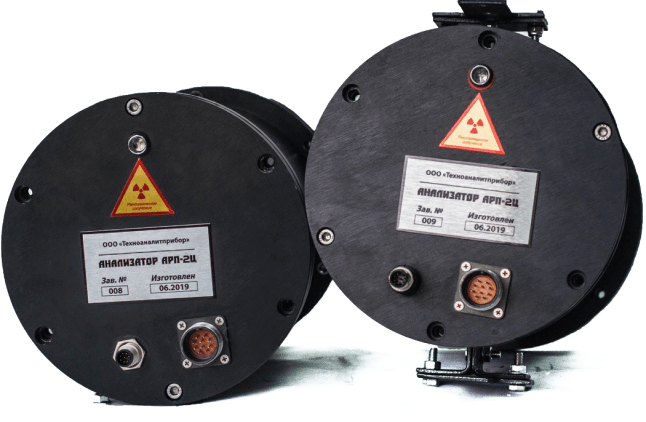

"ООО "Техноаналитприбор" - научно-производственная компания, специализирующаяся на внедрении и сопровождении оборудования для определения элементного состава руды в потоке для горно-обогатительных предприятий.

15-летний опыт работы сотрудников в сфере рентгенофлуоресцентного анализа позволил разработать поточный анализатор, обеспечивающий точный анализ руды и пульпы на всех этапах обогащения

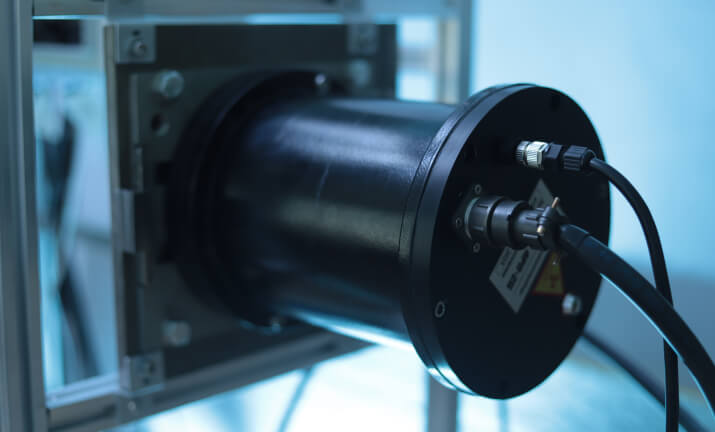

Контроль и автоматизация технологических процессов на горнодобывающих и горнообогатительных предприятиях с помощью поточного рентгенофлуоресцентного on-line анализатора АКП-1Ц.

Более, чем 15 летний опыт работы сотрудников в сфере рентгенофлуоресцентного анализа позволил разработать поточный анализатор, обеспечивающий точный анализ руды и пульпы на всех этапах обогащения - от входного контроля до анализа готового концентрата и хвостов.

Генеральный Директор компании - кандидат физико-математических наук (НИЯУ МИФИ). Тема диссертации "Разработка методов повышения чувствительности и точности флуоресцентного рентгенорадиометрического анализа состава сложных сред в широком диапазоне атомных номеров".

Сотрудники компании постоянно публикуют статьи в научных журналах и выступают на международных конференциях и выставках.

Почему это важно ?

Применение современных научных решений для усовершенствования управления технологическими процессами — это повышение стабильности технологических процессов и эффективности производства.

Измерение показателей качества

управление и контроль технологических процессов

Отсутствие пробоподготовки

оперативность, снижение затрат на подготовку и отбор проб

Увеличение качества флотации

оперативное реагирование и управление процессом

Автоматизация процессов

снижение «человеческого фактора»

Оперативность анализа

получение результатов в реальном времени

Всесторонняя оценка показателей

выявление потенциала улучшения

Полезные материалы

Обогащение руды

Новости

- «Техноаналитприбор» и его продукция попали на карту инновационных решений столицы 27 июля 2023

- Переговоры с коллегами из Индии 01 ноября 2022

- Участие в В2В встрече с предпринимателями из Индии 01 ноября 2022

- Встреча с представителями Норникеля 13 сентября 2022

- «УГОЛЬ РОССИИ и МАЙНИНГ» 2021 01 июня 2021

Вопросы и ответы

Радионуклидный источник не пробивает весь слой на ленте. Производится анализ поверхности слоя толщиной примерно несколького миллиметров. Но за счет большой площади засвета и непрерывного, поточного анализа мы получаем представительные данные.

Существует научное обоснование и практическое подтверждение, доказывающие, что для получение представительного анализа не требуется измерять всю толщину слоя.